Production and quality

Production process

Our parent company AKG produces all Jetfloat elements. The production process is certified by ISO 9001:2015 and

IATF 16949:2016

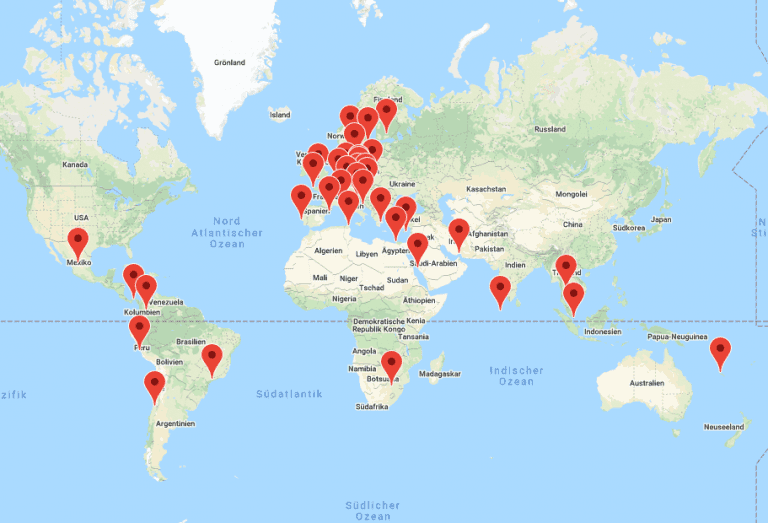

Experience

Experience in production and application since 1971.

JETFLOAT®INTERNATIONAL elements are made from the raw material LUPOLEN 5261 Z, a special high-density polyethylene (HD-PE). The producer’s production certificate confirms that this raw material is also produced strictly in accordance with ISO 9001 standards.

This material is the most suitable for modular pontoon systems.

All JETFLOAT elements and connecting bolts are blown from 100% pure Lupolen 5261 Z. No recycled material is used as it will decay in the sun and water within a few years

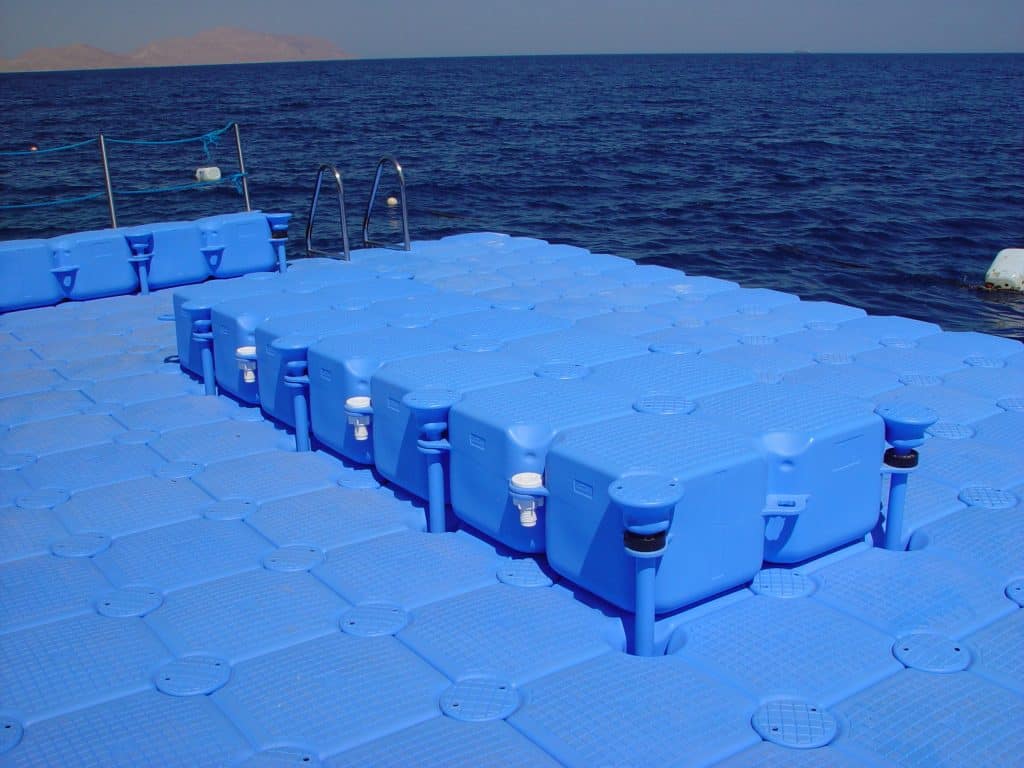

Flood caps

Concave base

The concave bottom guarantees better adhesion of the elements to the water surface.

Edge connector

The nuts of the edge connectors snap into the notches on the underside of the connecting lugs with the anti-twist device. The edge connectors and spacers are made from Lupolen 5261 Z in combination with another HD-PE type as an injection molded part.

Connecting bolt

The connecting bolts are equipped with a cam system for locking and also secured with locking knobs to prevent them from being pulled out. The connecting bolts can only be locked and opened with the special assembly key. Weight of the pin 600 gr, also consists of LUPOLEN 5261 Z.